Maine’s Pulp and Paper Industry

by Tom Seymour

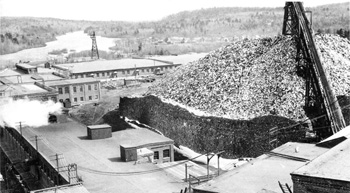

The St. Croix Paper Company pulp wood pile at the Woodland mill, built in 1905, on the St. Croix River in Baileyville, Maine. The paper-making industry in the U.S. switched from rags to wood pulp due to inadequate rags supplies in the 1870s. The company built a 2,000 foot wide dam across the St. Croix River. Flat area in left foreground is the roof of a two-story mill building. Photo courtesy Penobscot Marine Museum

Maine’s natural resources, her lumber and her rivers, ideally suited Maine as a place for papermaking. The industry began, however, using rags rather than wood in the papermaking process.

The Maine papermaking industry began around 1739 in a tiny, by today’s standards, mill on Westbrook’s Presumpscot River. The river supplied good water as well as power. This first mill used rags as its main ingredient in the papermaking process.

Then in 1854, Samuel Dennis Warren bought the Westbrook mill and this was the genesis of the S.D. Warren company. The mill quickly expanded under Warren’s guidance. Rags, however, were imported because domestic locally-obtained rags were not available in sufficient quantity. Only two years after its inception the Westbrook mill was importing more rags than any other mill in the world.

Soon after this a rag shortage compelled papermakers to seek another source of fiber. Inventors quickly embraced the challenge and poplar became the new substitute for rags. Since Maine was, and remains, such a heavily forested state and Maine’s rivers were available for not only power to operate machinery but also, clean water for the papermaking process, Maine papermaking quickly gained prominence on the world stage.

The first wood pulp in Maine had inauspicious beginnings, being manufactured in the lower floor of a sawmill in Topsham. Output from this new mill grew to 1 ton daily. Then in 1875 the Warren mill began using a blend of rags and wood fiber and by 1880, owned the distinction of being the world’s largest paper mill.

After this an American inventor found a way to heat liquefied wood fiber with a sulphur solution. But it was Sweden that began putting this new method into practice. In 1884, Maine adopted this papermaking method and this spurred the industry on to become a world player.

Mill History

Maine’s papermaking industry expanded at a rapid pace and by 1890 Maine had 25 different operating paper mills. The combined tonnage of pulp produced in these mills amounted to 1,701 tons daily.

During a 30-year period beginning in 1930, Maine became America’s biggest paper-producing state. Then in 1937 The Kraft pulping process gained ascendency and that same process remains the main process today. Kraft paper is strong (the word Kraft is German for “strong”). It produces some of the best-quality pulp. Using softwood trees such as balsam fir, the Kraft process attracted huge investments, which in turn allowed Maine mills to become a top producer of writing and printing paper and also, coated paper.

But the time drew near when Maine would lose its title as the nation’s No. 1 papermaking state. Wisconsin assumed top place and many new mills began production there. Furthermore, mills in the U.S. south began using fiber from southern pine, grown on pine plantations there.

In addition, mills in Wisconsin and Washington State, as well as those in the southern states, drew more investment from the various paper companies. Still a major paper producer, the writing was on the wall for Maine paper mills to begin losing ground to out-of-state producers.

Today, Maine faces competition not only from other U.S. states and Canada, but also new mills in Europe that came online beginning in the 1980s and that trend continued into the 1990s. After that, Brazil and Chile, with their vast forests, began building new mills and these put a severe crimp on Maine’s share of the pie.

Also, Asia is building new pulping facilities at a rapid rate. China, Indonesia and South Korea are all now in the papermaking business. And, of course, these new mills pay far less in labor costs than Maine, thereby nudging the Pine Tree State further back down the competitive ladder.

Because of this increased competition Maine has made capital improvements on existing mills and also reduced the labor force. Still, many of Maine’s mills have had no option but to shutter their doors.

All the same, Maine manages to remain competitive and Maine-made paper still stands as a valuable commodity despite downsizing and mill closures that have taken such a huge economic toll on many cities and towns throughout the state. Also, some papermakers have found niche markets, a far cry from the glory days of being number 1 on the papermaking list but better than not making paper at all.

Mill Closures

The Verso Paper Mill on the Penobscot River in Bucksport, Maine. Clean water was needed to make paper. Rivers also provided the transportation for pulp wood–1,701 tons of pulp a day for Maine mills in 1890. The river water was essential for liquifying the wood fiber and sulphur solution. Tom Seymour photo

Because of this enforced downsizing, many Maine workers have found themselves suddenly out of a job. When big mills such as those in Madison, East Millinocket, Lincoln, Old Town and Bucksport, to name a few, shut down the impact becomes more wide-reaching than it may appear.

Consider the communities that have mills, the diners, restaurants and other businesses that depend primarily on business from mill workers. And then we have the tax loss. Paper mills pay large property tax bills and many communities depend upon this revenue. Without it, property owners face higher taxes to pay for ever-increasing infrastructure costs.

Re-training programs abound and some ex-millworkers have made relatively seamless transitions to other modes of employment. But that can’t be said for everyone. Also, going from a high-paying job to a lesser-paying job means that amenities such as ATVs, new pickup trucks, new houses and the like are no longer part of the American dream, at least for these people.

Today, Maine’s northern timberlands continue to produce pulpwood for the pulp and paper industry. But Maine woodcutters, Maine mills and Maine haulers have taken a back seat to Canadian interests. Now, a drive through paper company lands will disclose the true extent of the switchover. It’s hard to find anyone from Maine working in the Maine woods.

To get an up-close and personal idea of the extent of this loss of Maine jobs, just take a ride on the Golden Road, a northern Maine highway created for and dedicated to the logging industry. Late afternoon of each and every day sees rays from the setting sun shining upon virtual convoys of log trucks, fully loaded and headed to Canada.

Gone are the little guys, independent loggers who, with their skidders and chainsaws, harvest small amounts of pulpwood to sell to local mills. These groups and individuals represented the last of the independent loggers, rugged people who made their own way and managed to pay for their homes, vehicles, children’s educations and so on. But with no outlets available for their product, these people have had their lives upended.

So with the loss of so many of our paper mills, Maine enters a new phase of its economic life. The good news here is that Maine people are resilient. Mainers will, as a whole, get past this and in time mill work will remain only in the memories of those who dedicated their working lives to the trade.