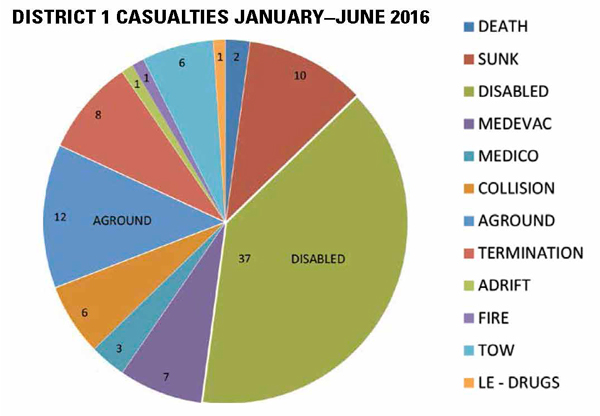

Aground and Disabled

There have been a total of 94 fishing vessel casualties logged in USCG District I between January 3 and June 2, 2016. This compares with 77 for a comparable period in 2015.

The two deaths in these 94 casualties were drug-related not fishing-related which is very concerning. That number should have been zero.

As this graph shows, aground and disabled vessels make up 49 of the 94 casualties.

Breaking out the Aground casualties gives us sparse information on how to prevent these casualties. Four vessels went aground because they broke from their moorings; for four groundings no cause was assigned; the remaining four groundings were from rudder damage, autopilot malfunction, loss of situational awareness and an interaction with a flipped 25’ USCG vessel. The lessons learned from these events are to check moorings carefully and frequently.

Disabled Casualties

Breaking out the 37 disabled casualties offers more insight into possible corrective or preventive actions.

“Engine casualty” was listed as the cause for 14 of the 37 disablements. Another five had engine-related issues such as blown clutch, reduction gear failure, transmission failure, fuel and battery issues.

Fred Mattera of NESTCO offers an extensive checklist for engine maintenance that ranges from daily checks to semiannual checks. Daily checks include engine controls and alarms; fluid levels of oil, coolant, reverse gear oil, power steering, battery electrolyte and hydraulic fluid; and start-up batteries. Weekly checks include inspections for/of fuel leaks, main engine fluid levels, fuel filters, and batteries and chargers. His monthly suggestion is to change main engine oil and oil filters before the maximum 400 hours; change oil and oil filters for auxillary gensets at 250-300 hours; change fuel filters for main engine and gensets; change air filters, and inspect all hose connections and hose clamps. Quarterly, Mr. Mattera suggests inspecting battery connections for corrosion and fuel lines for leaks.

The cause of eight (8) of 37 disablements was listed as unknown, however the next group of eight disablements were related to steering (2) rudder (2), fouled prop(3) or shaft issues (1) To help prevent disablements due to these problems, Mr. Mattera suggests the following daily actions: greasing the main shaft bearing; checking the drip rate at the propeller shaft and rudder post packing glands; and activating the steering mechanism by turning full right and left. Monthly checks include checking for corrosion and inspecting steering gear, rudder, packing gland and bearings. For the quarterly check he suggests that zincs, propellers, rudders and through-hull fittings should be checked by a diver.

Mr. Mattera’s complete Maintenance Checklist is available in the February 2015 issue of Commercial Fisheries News and in Appendix B of RESCUES: Responding to Emergencies at Sea and to Communities Under Extreme Stress by Madeleine Hall-Arber, Kristina Pinto, and Ann Backus and available at http://fishingpartnership.org/services/rescuemanual/.

Joel Woods photo

Sunk Vessels

For the 10 vessels listed in the database as “sunk”, four sank on their moorings, cause unknown, one sank at anchor, cause unknown and one sank at the pier; one sank on its mooring due to a faulty stuffing box, one sinking was classified as “unknown” and two sank because of a fire with a total of 5 persons saved. Out of the 10 eight were salvaged; only those that sank because of fire were lost.

In summary, following Fred Mattera’s check list will go a long way toward reducing the risk of a vessel casualty such as going aground, being disabled or sunk. And although loss of life was fortunately not an issue in these casualties, it could have happened. Let’s rev-up the maintenance for the remainder of the year and see if it makes a difference.

Reference: USCG District 1 Casualty Database to June 2, 2016.

Ann Backus, MS is an Instructor in Occupational Health at Harvard School of Public Health, 665 Huntington Ave., Boston MA 02115, 617-432-3327, abackus@hohp.harvard.edu.